Corrugated cardboard - basis of our litho-laminated boxes - is a resistant, light, hygienic, 100% recyclable and ultra-flexible material.

In order to better meet the expected properties of the packaging for any product, many paper weights and flute types are proposed so as to define the optimal combination in terms of protection, visual perception and environmental footprint.

Needs analysis

To determine this optimal cardboard combination, different parameters must be taken into account:

- What is the packed product (material, dimensions, weight, primary packaging)?

- Is it for a unit package or for a multipack?

- How will the packaging be transported, stored and supplied to the end consumer?

- What is the expected printing quality?

Corrugated cardboard combination

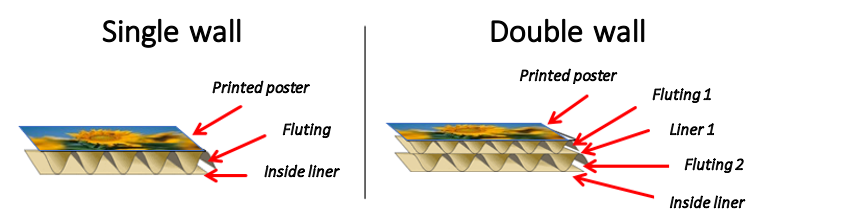

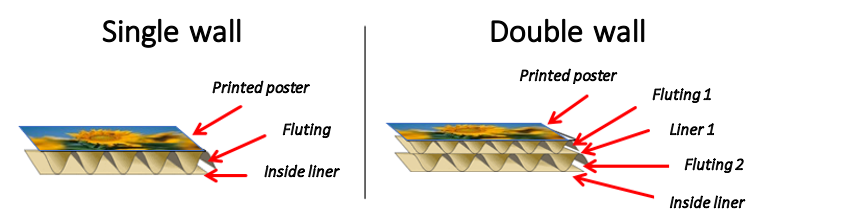

There are different types of corrugated cardboard: single face, single wall, double wall, triple wall... Sales packages are mainly in:

Each component has a specific function:

| INSIDE LINER |

Cohesion and resistance necessary for protection of the content |

| FLUTING |

Elasticity needed for shock absorption, rigidity, resistance towards stacking's constraints |

| PRINTED POSTER |

Support for printing |

Starch glues allow to assemble the medium with inside liner and printed poster.

Choice of papers

Main papers used by LGR Packaging:

Main papers used by LGR Packaging:

Printed posters: papers for printing

- Recycled liner

- Coated kraft liner - offering higher rigidity and mechanical resistance

Inside liners and fluting: papers for corrugating

- Light recycled liner

- Heavy recycled liner

- White top recycled liner

- Fluting with barrier properties against humidity.

Relying on project's input data, the choice of papers will be made based on each material's aspect, weight, thickness and properties.

Choice of flutes

The flute's profile defines the level of resistance and elasticity of the packaging.

| Flute's type |

C FLUTE

"big" |

B FLUTE

"small" |

E FLUTE

"micro" |

F FLUTE

"mini micro" |

G FLUTE

"super mini micro" |

Thickness

(printed poster + fluting + inside liner) |

4 mm |

3 mm |

1.8 mm |

1.2 mm |

0.7 à 0.9 mm |

| Properties |

Flute adapted to heavy products |

Good resistance to flat crush strength |

Relatively flat surface for high quality printing applications |

Great price-quality ratio between E and G, lower fiber content |

Flexibility, strong alternative to folding carton, printability |

The double wall fluting is a combination of different profiles: F/E, F/B, E/E, E/B, B/C, etc.

- Thinner flutes allow to reduce volumes (logistics optimization), improve the aesthetic outer appearance (less wavy, thinner board side) and excellent compression strength & crush resistance.

- Thicker flutes allow a higher rigidity for packaging, a better protection of the product and excellent puncture and crush resistant properties.

Input data and utilization for the end user must then be taken into account in order to determine the optimal combination for the box.

Applications

HEAVY PRODUCTS

HEAVY PRODUCTS

- Heavy papers

- Flute: E, B, C and combinations

STANDARD PRODUCTS

STANDARD PRODUCTS

- Medium papers

- Flute: all kinds

LIGHT PRODUCTS

LIGHT PRODUCTS

- Light papers

- Flute: all kinds

VERY LIGHT PRODUCTS

VERY LIGHT PRODUCTS

- Light papers

- Flute: E and G

Main papers used by LGR Packaging:

Main papers used by LGR Packaging: